ASME/ANSI FLANGES

Longan flanges meet ASME/ANSI B16.5 and B16.47 (Series A & B) for guaranteed compatibility and performance. Connect pipes, valves, and pumps with confidence.

Home » ASME Flange

PRODUCT CATALOG

Get Instant Data & Drawings for Your custom flange Solution

CHOOSE YOUR FLANGE PRESSURE CLASS BELOW

ASME b16.5 Slip On Flange Dimensions

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 90 | 60.3 | 16 | 4 | M14 | 9.6 | 22.5 | 30 | 14 |

| 20 | 3/4 | 26.9 | 100 | 69.9 | 16 | 4 | M14 | 11.2 | 27.5 | 38 | 14 |

| 25 | 1 | 33.7 | 110 | 79.4 | 16 | 4 | M14 | 12.7 | 34.5 | 49 | 16 |

| 32 | 1 1/4 | 42.4 | 115 | 88.9 | 16 | 4 | M14 | 14.3 | 43.5 | 59 | 19 |

| 40 | 1 1/2 | 48.3 | 125 | 98.4 | 16 | 4 | M14 | 15.9 | 49.5 | 65 | 21 |

| 50 | 2 | 60.3 | 150 | 120.7 | 18 | 4 | M16 | 17.5 | 61.5 | 78 | 24 |

| 65 | 2 1/2 | 76.1 | 180 | 139.7 | 18 | 4 | M16 | 20.7 | 77.6 | 90 | 27 |

| 80 | 3 | 88.9 | 190 | 152.4 | 18 | 4 | M16 | 22.3 | 90.5 | 108 | 29 |

| 100 | 4 | 114.3 | 230 | 190.5 | 18 | 8 | M16 | 22.3 | 116.0 | 135 | 32 |

| 125 | 5 | 139.7 | 255 | 215.9 | 22 | 8 | M20 | 22.3 | 143.5 | 164 | 35 |

| 150 | 6 | 168.3 | 280 | 241.3 | 22 | 8 | M20 | 23.9 | 170.5 | 192 | 38 |

| 200 | 8 | 219.1 | 345 | 298.5 | 22 | 8 | M20 | 27.0 | 221.5 | 246 | 43 |

| 250 | 10 | 273.0 | 405 | 362 | 26 | 12 | M24 | 28.6 | 276.5 | 305 | 48 |

| 300 | 12 | 323.9 | 485 | 431.8 | 26 | 12 | M24 | 30.2 | 328.0 | 365 | 54 |

| 350 | 14 | 355.6 | 535 | 476.3 | 30 | 12 | M27 | 33.4 | 360.0 | 400 | 56 |

| 400 | 16 | 406.4 | 595 | 539.8 | 30 | 16 | M27 | 35.0 | 411.0 | 457 | 62 |

| 450 | 18 | 457 | 635 | 577.9 | 33 | 16 | M30 | 38.1 | 462.0 | 505 | 67 |

| 500 | 20 | 508 | 700 | 635 | 33 | 20 | M30 | 41.3 | 513.5 | 559 | 71 |

| 600 | 24 | 610 | 815 | 749.3 | 36 | 20 | M33 | 46.1 | 616.5 | 663 | 81 |

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 95 | 66.7 | 16 | 4 | M14 | 12.7 | 22.5 | 38 | 21 |

| 20 | 3/4 | 26.9 | 115 | 82.6 | 18 | 4 | M16 | 14.3 | 27.5 | 48 | 24 |

| 25 | 1 | 33.7 | 125 | 88.9 | 18 | 4 | M16 | 15.9 | 34.5 | 54 | 25 |

| 32 | 1 1/4 | 42.4 | 135 | 98.4 | 18 | 4 | M16 | 17.5 | 43.5 | 64 | 25 |

| 40 | 1 1/2 | 48.3 | 155 | 114.3 | 22 | 4 | M20 | 19.1 | 49.5 | 70 | 29 |

| 50 | 2 | 60.3 | 165 | 127 | 18 | 8 | M16 | 20.7 | 61.5 | 84 | 32 |

| 65 | 2 1/2 | 76.1 | 190 | 149.2 | 22 | 8 | M20 | 23.9 | 77.6 | 100 | 37 |

| 80 | 3 | 88.9 | 210 | 168.3 | 22 | 8 | M20 | 27 | 90.5 | 117 | 41 |

| 100 | 4 | 114.3 | 255 | 200 | 22 | 8 | M20 | 30.2 | 116 | 146 | 46 |

| 125 | 5 | 139.7 | 280 | 235 | 22 | 8 | M20 | 33.4 | 143.5 | 178 | 49 |

| 150 | 6 | 168.3 | 320 | 269.9 | 22 | 12 | M20 | 35 | 170.5 | 206 | 51 |

| 200 | 8 | 219.1 | 380 | 330.2 | 26 | 12 | M24 | 39.7 | 221.5 | 260 | 60 |

| 250 | 10 | 273 | 445 | 387.4 | 30 | 16 | M27 | 46.1 | 276.5 | 321 | 65 |

| 300 | 12 | 323.9 | 520 | 450.8 | 33 | 16 | M30 | 49.3 | 328 | 375 | 71 |

| 350 | 14 | 355.6 | 585 | 514.4 | 33 | 20 | M30 | 52.4 | 360 | 425 | 75 |

| 400 | 16 | 406.4 | 650 | 571.5 | 36 | 20 | M33 | 55.6 | 411 | 483 | 81 |

| 450 | 18 | 457 | 710 | 628.6 | 36 | 24 | M33 | 58.8 | 462 | 533 | 87 |

| 500 | 20 | 508 | 775 | 685.8 | 36 | 24 | M33 | 62 | 513.5 | 587 | 94 |

| 600 | 24 | 610 | 915 | 812.8 | 42 | 24 | M39X3 | 68.3 | 616.5 | 702 | 105 |

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 95 | 66.7 | 16 | 4 | M14 | 14.3 | 22.5 | 38 | 22 |

| 20 | 3/4 | 26.9 | 115 | 82.6 | 18 | 4 | M16 | 15.9 | 27.5 | 48 | 25 |

| 25 | 1 | 33.7 | 125 | 88.9 | 18 | 4 | M16 | 17.5 | 34.5 | 54 | 27 |

| 32 | 1 1/4 | 42.4 | 135 | 88.4 | 18 | 4 | M16 | 20.7 | 43.5 | 64 | 29 |

| 40 | 1 1/2 | 48.3 | 155 | 114.3 | 22 | 4 | M20 | 22.3 | 49.5 | 70 | 32 |

| 50 | 2 | 60.3 | 165 | 127 | 18 | 8 | M16 | 25.4 | 61.5 | 84 | 37 |

| 65 | 2 1/2 | 76.1 | 190 | 149.2 | 22 | 8 | M20 | 28.6 | 77.6 | 100 | 41 |

| 80 | 3 | 88.9 | 210 | 168.3 | 22 | 8 | M20 | 31.8 | 90.5 | 117 | 46 |

| 100 | 4 | 114.3 | 275 | 215.9 | 26 | 8 | M24 | 38.1 | 116 | 152 | 54 |

| 125 | 5 | 139.7 | 330 | 266.7 | 30 | 8 | M27 | 44.5 | 143.5 | 189 | 60 |

| 150 | 6 | 168.3 | 355 | 292.1 | 30 | 12 | M27 | 47.7 | 170.5 | 222 | 67 |

| 200 | 8 | 219.1 | 420 | 349.2 | 33 | 12 | M30 | 55.6 | 221.5 | 273 | 76 |

| 250 | 10 | 273 | 510 | 431.8 | 36 | 16 | M33 | 63.5 | 276.5 | 343 | 86 |

| 300 | 12 | 323.9 | 560 | 489 | 36 | 20 | M33 | 66.7 | 328 | 400 | 92 |

| 350 | 14 | 355.6 | 605 | 527 | 39 | 20 | M36X3 | 69.9 | 360 | 432 | 94 |

| 400 | 16 | 406.4 | 685 | 603.2 | 42 | 20 | M39X3 | 76.2 | 411 | 495 | 106 |

| 450 | 18 | 457 | 745 | 654 | 45 | 20 | M42X3 | 82.6 | 462 | 546 | 117 |

| 500 | 20 | 508 | 815 | 723.9 | 45 | 24 | M42X3 | 88.9 | 513.5 | 610 | 127 |

| 600 | 24 | 610 | 940 | 838.2 | 51 | 24 | M48X3 | 101.6 | 616.5 | 718 | 140 |

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 120 | 82.6 | 22 | 4 | M20 | 22.3 | 22.5 | 38 | 32 |

| 20 | 3/4 | 26.9 | 130 | 88.9 | 22 | 4 | M20 | 25.4 | 27.5 | 44 | 35 |

| 25 | 1 | 33.7 | 150 | 101.6 | 26 | 4 | M24 | 28.6 | 34.5 | 52 | 41 |

| 32 | 1 1/4 | 42.4 | 160 | 111.1 | 26 | 4 | M24 | 28.6 | 43.5 | 64 | 41 |

| 40 | 1 1/2 | 48.3 | 180 | 123.8 | 30 | 4 | M27 | 31.8 | 49.5 | 70 | 44 |

| 50 | 2 | 60.3 | 215 | 165.1 | 26 | 8 | M24 | 38.1 | 61.5 | 105 | 57 |

| 65 | 2 1/2 | 76.1 | 245 | 190.5 | 30 | 8 | M27 | 41.3 | 77.6 | 124 | 64 |

| 80 | 3 | 88.9 | 240 | 190.5 | 26 | 8 | M24 | 38.1 | 90.5 | 127 | 54 |

| 100 | 4 | 114.3 | 290 | 235 | 33 | 8 | M30 | 44.5 | 116 | 159 | 70 |

| 125 | 5 | 139.7 | 350 | 279.4 | 36 | 8 | M33 | 50.8 | 143.5 | 190 | 79 |

| 150 | 6 | 168.3 | 380 | 317.5 | 33 | 12 | M30 | 55.6 | 170.5 | 235 | 86 |

| 200 | 8 | 219.1 | 470 | 393.7 | 39 | 12 | M36X3 | 63.5 | 221.5 | 298 | 102 |

| 250 | 10 | 273 | 545 | 469.9 | 39 | 16 | M36X3 | 69.9 | 276.5 | 368 | 108 |

| 300 | 12 | 323.9 | 610 | 533.4 | 39 | 20 | M36X3 | 79.4 | 328 | 419 | 117 |

| 350 | 14 | 355.6 | 640 | 558.8 | 42 | 20 | M39X3 | 85.8 | 360 | 451 | 130 |

| 400 | 16 | 406.4 | 705 | 616 | 45 | 20 | M42X3 | 88.9 | 411 | 508 | 133 |

| 450 | 18 | 457 | 785 | 685.8 | 51 | 20 | M48X3 | 101.6 | 462 | 565 | 152 |

| 500 | 20 | 508 | 855 | 749.3 | 55 | 20 | M52X3 | 108 | 513.5 | 622 | 159 |

| 600 | 24 | 610 | 1040 | 901.7 | 68 | 20 | M64X3 | 139.7 | 616.5 | 749 | 203 |

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 120 | 82.6 | 22 | 4 | M20 | 22.3 | 22.5 | 38 | 32 |

| 20 | 3/4 | 26.9 | 130 | 88.9 | 22 | 4 | M20 | 25.4 | 27.5 | 44 | 35 |

| 25 | 1 | 33.7 | 150 | 101.6 | 26 | 4 | M24 | 28.6 | 34.5 | 52 | 41 |

| 32 | 1 1/4 | 42.4 | 160 | 111.1 | 26 | 4 | M24 | 28.6 | 43.5 | 64 | 41 |

| 40 | 1 1/2 | 48.3 | 180 | 123.8 | 30 | 4 | M27 | 31.8 | 49.5 | 70 | 44 |

| 50 | 2 | 60.3 | 215 | 165.1 | 26 | 8 | M24 | 38.1 | 61.5 | 105 | 57 |

| 65 | 2 1/2 | 76.1 | 245 | 190.5 | 30 | 8 | M27 | 41.3 | 77.6 | 124 | 64 |

ASME b16.5 Weld Neck Flange Dimensions

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 90 | 60.3 | 16 | 4 | M14 | 9.6 | 15.5 | 30 | 46 |

| 20 | 3/4 | 26.9 | 100 | 69.9 | 16 | 4 | M14 | 11.2 | 21 | 38 | 51 |

| 25 | 1 | 33.7 | 110 | 79.4 | 16 | 4 | M14 | 12.7 | 27 | 49 | 54 |

| 32 | 1 1/4 | 42.4 | 115 | 88.9 | 16 | 4 | M14 | 14.3 | 35 | 59 | 56 |

| 40 | 1 1/2 | 48.3 | 125 | 98.4 | 16 | 4 | M14 | 15.9 | 41 | 65 | 60 |

| 50 | 2 | 60.3 | 150 | 120.7 | 18 | 4 | M16 | 17.5 | 52 | 78 | 62 |

| 65 | 2 1/2 | 76.1 | 180 | 139.7 | 18 | 4 | M16 | 20.7 | 66 | 90 | 68 |

| 80 | 3 | 88.9 | 190 | 152.4 | 18 | 4 | M16 | 22.3 | 77.5 | 108 | 68 |

| 100 | 4 | 114.3 | 230 | 190.5 | 18 | 8 | M16 | 22.3 | 101.5 | 135 | 75 |

| 125 | 5 | 139.7 | 255 | 215.9 | 22 | 8 | M20 | 22.3 | 127 | 164 | 87 |

| 150 | 6 | 168.3 | 280 | 241.3 | 22 | 8 | M20 | 23.9 | 154 | 192 | 87 |

| 200 | 8 | 219.1 | 345 | 298.5 | 22 | 8 | M20 | 27 | 203 | 246 | 100 |

| 250 | 10 | 273 | 405 | 362 | 26 | 12 | M24 | 28.6 | 255 | 305 | 100 |

| 300 | 12 | 323.9 | 485 | 431.8 | 26 | 12 | M24 | 30.2 | 303.5 | 365 | 113 |

| 350 | 14 | 355.6 | 535 | 476.3 | 30 | 12 | M27 | 33.4 | – | 400 | 125 |

| 400 | 16 | 406.4 | 595 | 539.8 | 30 | 16 | M27 | 35 | – | 457 | 125 |

| 450 | 18 | 457 | 635 | 577.9 | 33 | 16 | M30 | 38.1 | – | 505 | 138 |

| 500 | 20 | 508 | 700 | 635 | 33 | 20 | M30 | 41.3 | – | 559 | 143 |

| 600 | 24 | 610 | 815 | 749.3 | 36 | 20 | M33 | 46.1 | – | 663 | 151 |

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 95 | 66.7 | 16 | 4 | M14 | 12.7 | 15.5 | 38 | 51 |

| 20 | 3/4 | 26.9 | 115 | 82.6 | 18 | 4 | M16 | 14.3 | 21 | 48 | 56 |

| 25 | 1 | 33.7 | 125 | 88.9 | 18 | 4 | M16 | 15.9 | 27 | 54 | 60 |

| 32 | 1 1/4 | 42.4 | 135 | 98.4 | 18 | 4 | M16 | 17.5 | 35 | 64 | 64 |

| 40 | 1 1/2 | 48.3 | 155 | 114.3 | 22 | 4 | M20 | 19.1 | 41 | 70 | 67 |

| 50 | 2 | 60.3 | 165 | 127 | 18 | 8 | M16 | 20.7 | 52 | 84 | 68 |

| 65 | 2 1/2 | 76.1 | 190 | 149.2 | 22 | 8 | M20 | 23.9 | 66 | 100 | 75 |

| 80 | 3 | 88.9 | 210 | 168.3 | 22 | 8 | M20 | 27 | 77.5 | 117 | 78 |

| 100 | 4 | 114.3 | 255 | 200 | 22 | 8 | M20 | 30.2 | 101.5 | 146 | 84 |

| 125 | 5 | 139.7 | 280 | 235 | 22 | 8 | M20 | 33.4 | 127 | 178 | 97 |

| 150 | 6 | 168.3 | 320 | 269.9 | 22 | 12 | M20 | 35 | 154 | 206 | 97 |

| 200 | 8 | 219.1 | 380 | 330.2 | 26 | 12 | M24 | 39.7 | 203 | 260 | 110 |

| 250 | 10 | 273 | 445 | 387.4 | 30 | 16 | M27 | 46.1 | 255 | 321 | 116 |

| 300 | 12 | 323.9 | 520 | 450.8 | 33 | 16 | M30 | 49.3 | 303.5 | 375 | 129 |

| 350 | 14 | 355.6 | 585 | 514.4 | 33 | 20 | M30 | 52.4 | – | 425 | 141 |

| 400 | 16 | 406.4 | 650 | 571.5 | 36 | 20 | M33 | 55.6 | – | 483 | 144 |

| 450 | 18 | 457 | 710 | 628.6 | 36 | 24 | M33 | 58.8 | – | 533 | 157 |

| 500 | 20 | 508 | 775 | 685.8 | 36 | 24 | M33 | 62 | – | 587 | 160 |

| 600 | 24 | 610 | 915 | 812.8 | 42 | 24 | M39X3 | 68.3 | – | 702 | 167 |

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 95 | 66.7 | 16 | 4 | M14 | 14.3 | – | 38 | 52 |

| 20 | 3/4 | 26.9 | 115 | 82.6 | 18 | 4 | M16 | 15.9 | – | 48 | 57 |

| 25 | 1 | 33.7 | 125 | 88.9 | 18 | 4 | M16 | 17.5 | – | 54 | 62 |

| 32 | 1 1/4 | 42.4 | 135 | 98.4 | 18 | 4 | M16 | 20.7 | – | 64 | 67 |

| 40 | 1 1/2 | 48.3 | 155 | 114.3 | 22 | 4 | M20 | 22.3 | – | 70 | 70 |

| 50 | 2 | 60.3 | 165 | 127 | 18 | 8 | M16 | 25.4 | – | 84 | 73 |

| 65 | 2 1/2 | 76.1 | 190 | 149.2 | 22 | 8 | M20 | 28.6 | – | 100 | 79 |

| 80 | 3 | 88.9 | 210 | 168.3 | 22 | 8 | M20 | 31.8 | – | 117 | 83 |

| 100 | 4 | 114.3 | 275 | 215.9 | 26 | 8 | M24 | 38.1 | – | 152 | 102 |

| 125 | 5 | 139.7 | 330 | 266.7 | 30 | 8 | M27 | 44.5 | – | 189 | 114 |

| 150 | 6 | 168.3 | 355 | 292.1 | 30 | 12 | M27 | 47.7 | – | 222 | 117 |

| 200 | 8 | 219.1 | 420 | 349.2 | 33 | 12 | M30 | 55.6 | – | 273 | 133 |

| 250 | 10 | 273 | 510 | 431.8 | 36 | 16 | M33 | 63.5 | – | 343 | 152 |

| 300 | 12 | 323.9 | 560 | 489 | 36 | 20 | M33 | 66.7 | – | 400 | 156 |

| 350 | 14 | 355.6 | 605 | 527 | 39 | 20 | M36X3 | 69.9 | – | 432 | 165 |

| 400 | 16 | 406.4 | 685 | 603.2 | 42 | 20 | M39X3 | 76.2 | – | 495 | 178 |

| 450 | 18 | 457 | 745 | 654 | 45 | 20 | M42X3 | 82.6 | – | 546 | 184 |

| 500 | 20 | 508 | 815 | 723.9 | 45 | 24 | M42X3 | 88.9 | – | 610 | 190 |

| 600 | 24 | 610 | 940 | 838.2 | 51 | 24 | M48X3 | 101.6 | – | 718 | 203 |

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 120 | 82.6 | 22 | 4 | M20 | 22.3 | – | 38 | 60 |

| 20 | 3/4 | 26.9 | 130 | 88.9 | 22 | 4 | M20 | 25.4 | – | 44 | 70 |

| 25 | 1 | 33.7 | 150 | 101.6 | 26 | 4 | M24 | 28.6 | – | 52 | 73 |

| 32 | 1 1/4 | 42.4 | 160 | 111.1 | 26 | 4 | M24 | 28.6 | – | 64 | 73 |

| 40 | 1 1/2 | 48.3 | 180 | 123.8 | 30 | 4 | M27 | 31.8 | – | 70 | 83 |

| 50 | 2 | 60.3 | 215 | 165.1 | 26 | 8 | M24 | 38.1 | – | 105 | 102 |

| 65 | 2 1/2 | 76.1 | 245 | 190.5 | 30 | 8 | M27 | 41.3 | – | 124 | 105 |

| 80 | 3 | 88.9 | 240 | 190.5 | 26 | 8 | M24 | 38.1 | – | 127 | 102 |

| 100 | 4 | 114.3 | 290 | 235 | 33 | 8 | M30 | 44.5 | – | 159 | 114 |

| 125 | 5 | 139.7 | 350 | 279.4 | 36 | 8 | M33 | 50.8 | – | 190 | 127 |

| 150 | 6 | 168.3 | 380 | 317.5 | 33 | 12 | M30 | 55.6 | – | 235 | 140 |

| 200 | 8 | 219.1 | 470 | 393.7 | 39 | 12 | M36X3 | 63.5 | – | 298 | 162 |

| 250 | 10 | 273 | 545 | 469.9 | 39 | 16 | M36X3 | 69.9 | – | 368 | 184 |

| 300 | 12 | 323.9 | 610 | 533.4 | 39 | 20 | M36X3 | 79.4 | – | 419 | 200 |

| 350 | 14 | 355.6 | 640 | 558.8 | 42 | 20 | M39X3 | 85.8 | – | 451 | 213 |

| 400 | 16 | 406.4 | 705 | 616 | 45 | 20 | M42X3 | 88.9 | – | 508 | 216 |

| 450 | 18 | 457 | 785 | 685.8 | 51 | 20 | M48X3 | 101.6 | – | 565 | 229 |

| 500 | 20 | 508 | 855 | 749.3 | 55 | 20 | M52X3 | 108 | – | 622 | 248 |

| 600 | 24 | 610 | 1040 | 901.7 | 68 | 20 | M64X3 | 139.7 | – | 749 | 292 |

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 120 | 82.6 | 22 | 4 | M20 | 22.3 | – | 38 | 60 |

| 20 | 3/4 | 26.9 | 130 | 88.9 | 22 | 4 | M20 | 25.4 | – | 44 | 70 |

| 25 | 1 | 33.7 | 150 | 101.6 | 26 | 4 | M24 | 28.6 | – | 52 | 73 |

| 32 | 1 1/4 | 42.4 | 160 | 111.1 | 26 | 4 | M24 | 28.6 | – | 64 | 73 |

| 40 | 1 1/2 | 48.3 | 180 | 123.8 | 30 | 4 | M27 | 31.8 | – | 70 | 83 |

| 50 | 2 | 60.3 | 215 | 165.1 | 26 | 8 | M24 | 38.1 | – | 105 | 102 |

| 65 | 2 1/2 | 76.1 | 245 | 190.5 | 30 | 8 | M27 | 41.3 | – | 124 | 105 |

| 80 | 3 | 88.9 | 265 | 203.2 | 33 | 8 | M30 | 47.7 | – | 133 | 117 |

| 100 | 4 | 114.3 | 310 | 241.3 | 36 | 8 | M33 | 54 | – | 162 | 124 |

| 125 | 5 | 139.7 | 375 | 292.1 | 42 | 8 | M39X3 | 73.1 | – | 197 | 156 |

| 150 | 6 | 168.3 | 395 | 317.5 | 39 | 12 | M36X3 | 82.6 | – | 229 | 171 |

| 200 | 8 | 219.1 | 485 | 393.7 | 45 | 12 | M42X3 | 92.1 | – | 292 | 213 |

| 250 | 10 | 273 | 585 | 482.6 | 51 | 12 | M48X3 | 108 | – | 368 | 254 |

| 300 | 12 | 323.9 | 675 | 571.5 | 55 | 16 | M52X3 | 123.9 | – | 451 | 283 |

| 350 | 14 | 355.6 | 750 | 635 | 60 | 16 | M56X3 | 133.4 | – | 495 | 298 |

| 400 | 16 | 406.4 | 825 | 704.8 | 68 | 16 | M64X3 | 146.1 | – | 552 | 311 |

| 450 | 18 | 457 | 915 | 774.7 | 74 | 16 | M70X3 | 162 | – | 597 | 327 |

| 500 | 20 | 508 | 985 | 831.8 | 80 | 16 | M76X3 | 177.8 | – | 641 | 356 |

| 600 | 24 | 610 | 1170 | 990.6 | 94 | 16 | M90X3 | 203.2 | – | 762 | 406 |

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 135 | 88.9 | 22 | 4 | M20 | 30.2 | – | 43 | 73 |

| 20 | 3/4 | 26.9 | 140 | 95.2 | 22 | 4 | M20 | 31.8 | – | 51 | 79 |

| 25 | 1 | 33.7 | 160 | 108 | 26 | 4 | M24 | 35 | – | 57 | 89 |

| 32 | 1 1/4 | 42.4 | 185 | 130.2 | 30 | 4 | M27 | 38.1 | – | 73 | 95 |

| 40 | 1 1/2 | 48.3 | 205 | 146 | 33 | 4 | M30 | 44.5 | – | 79 | 111 |

| 50 | 2 | 60.3 | 235 | 171.4 | 30 | 8 | M27 | 50.9 | – | 95 | 127 |

| 65 | 21/2 | 76.1 | 265 | 196.8 | 33 | 8 | M30 | 57.2 | – | 114 | 143 |

| 80 | 3 | 88.9 | 305 | 228.6 | 36 | 8 | M33 | 66.7 | – | 133 | 168 |

| 100 | 4 | 114.3 | 355 | 273 | 42 | 8 | M39X3 | 76.2 | – | 165 | 190 |

| 125 | 5 | 139.7 | 420 | 323.8 | 48 | 8 | M45X3 | 92.1 | – | 203 | 229 |

| 150 | 6 | 168.3 | 485 | 368.3 | 55 | 8 | M52X3 | 108 | – | 235 | 273 |

| 200 | 8 | 219.1 | 550 | 438.2 | 55 | 12 | M52X3 | 127 | – | 305 | 318 |

| 250 | 10 | 273 | 675 | 539.8 | 68 | 12 | M64X3 | 165.1 | – | 375 | 419 |

| 300 | 12 | 323.9 | 760 | 619.1 | 74 | 12 | M70X3 | 184.2 | – | 441 | 464 |

ASME b16.5 Socket Weld Flange Dimensions

| Nominal size | Steel pipe outer diameter A | Flange outer diameter D | Connection size | flange thickness C | Flange inner diameter B1 | Socket | Flange neck big end N | Flange height H | Theoretical weight Kg | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Bolt hole center circle diameter K | Bold hole diameter L | Bolt hole Quantity n(pieces) | B2 | U | |||||||||||

| 15 | 1/2 | 21.3 | 90 | 88.9 | 60.3 | 16 | 15.7 | 4 | 9.6 | 15.5 | 15.7 | 22.5 | 22.4 | 10 | 30 | 14 | 0.42 |

| 20 | 3/4 | 26.9 | 100 | 98.6 | 69.9 | 16 | 15.7 | 4 | 11.2 | 21 | 20.8 | 27.5 | 27.7 | 11 | 38 | 14 | 0.59 |

| 25 | 1 | 33.7 | 110 | 108 | 79.4 | 16 | 15.7 | 4 | 12.7 | 27 | 26.7 | 34.5 | 34.5 | 13 | 49 | 16 | 0.81 |

| 32 | 1 1/4 | 42.4 | 115 | 117.3 | 88.9 | 16 | 15.7 | 4 | 14.3 | 35 | 35.1 | 43.5 | 43.2 | 14 | 59 | 19 | 1.07 |

| 40 | 1 1/2 | 48.3 | 125 | 127 | 98.4 | 16 | 15.7 | 4 | 15.9 | 41 | 40.9 | 49.5 | 49.5 | 16 | 65 | 21 | 1.36 |

| 50 | 2 | 60.3 | 150 | 152.4 | 120.7 | 18 | 19.1 | 4 | 17.5 | 52 | 52.6 | 61.5 | 62 | 17 | 78 | 24 | 2.1 |

| 65 | 2 1/2 | 76.1 | 180 | 177.8 | 139.7 | 18 | 19.1 | 4 | 20.7 | 66 | 62.7 | 77.6 | 74.7 | 19 | 90 | 27 | 3.33 |

| 80 | 3 | 88.9 | 190 | 190.5 | 152.4 | 18 | 19.1 | 4 | 22.3 | 77.5 | 78 | 90.5 | 90.7 | 21 | 108 | 29 | 3.9 |

Note: The inner diameter B1 of the flange is determined by the wall thickness of the steel pipe. The user should indicate it when ordering. The flange inner diameter B1 listed in the table is equivalent to a steel pipe with a wall thickness of Sch40

| Nominal size | Steel pipe outer diameter A | Flange outer diameter D | Connection size | flange thickness C | Flange inner diameter B1 | Socket | Flange neck big end N | Flange height H | Theoretical weight Kg | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Bolt hole center circle diameter K | Bold hole diameter L | Bolt hole Quantity n(pieces) | B2 | U | |||||||||||

| 15 | ½ | 21.3 | 95 | 88.9 | 66.7 | 16 | 15.7 | 4 | 12.7 | 15.5 | 15.7 | 22.5 | 22.4 | 10 | 38 | 21 | 0.66 |

| 20 | ¾ | 26.9 | 115 | 98.6 | 82.6 | 18 | 15.7 | 4 | 14.3 | 21 | 20.8 | 27.5 | 27.7 | 11 | 48 | 24 | 1.15 |

| 25 | 1 | 33.7 | 125 | 108 | 88.9 | 18 | 15.7 | 4 | 15.9 | 27 | 26.7 | 34.5 | 34.5 | 13 | 54 | 25 | 1.4 |

| 32 | 1 ¼ | 42.4 | 135 | 117.3 | 98.4 | 18 | 15.7 | 4 | 17.5 | 35 | 35.1 | 43.5 | 43.2 | 14 | 64 | 25 | 1.75 |

| 40 | 1 ½ | 48.3 | 155 | 127 | 114.3 | 22 | 15.7 | 4 | 19.1 | 41 | 40.9 | 49.5 | 49.5 | 16 | 70 | 29 | 2.55 |

| 50 | 2 | 60.3 | 165 | 152.4 | 127 | 18 | 19.1 | 8 | 20.7 | 52 | 52.6 | 61.5 | 62 | 17 | 84 | 32 | 2.93 |

| 65 | 2 ½ | 76.1 | 190 | 177.8 | 149.2 | 22 | 19.1 | 8 | 23.9 | 66 | 62.7 | 77.6 | 74.7 | 19 | 100 | 37 | 4.4 |

| 80 | 3 | 88.9 | 210 | 190.5 | 168.3 | 22 | 19.1 | 8 | 27 | 77.5 | 78 | 90.5 | 90.7 | 21 | 117 | 41 | 5.92 |

Note: The inner diameter B1 of the flange is determined by the wall thickness of the steel pipe. The user should indicate it when ordering. The flange inner diameter B1 listed in the table is equivalent to a steel pipe with a wall thickness of Sch40

| Nominal size | Steel pipe outer diameter A | Flange outer diameter D | Connection size | flange thickness C | Flange inner diameter B1 | Socket | Flange neck big end N | Flange height H | Theoretical weight Kg | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Bolt hole center circle diameter K | Bold hole diameter L | Bolt hole Quantity n(pieces) | B2 | U | ||||||||||

| 15 | 1/2 | 21.3 | 95 | 88.9 | 66.7 | 16 | 15.7 | 4 | 14.3 | – | 22.5 | 22.4 | 10 | 38 | 22 | 0.76 |

| 20 | 3/4 | 26.9 | 115 | 98.6 | 82.6 | 18 | 15.7 | 4 | 15.9 | – | 27.5 | 27.7 | 11 | 48 | 25 | 1.29 |

| 25 | 1 | 33.7 | 125 | 108 | 88.9 | 18 | 15.7 | 4 | 17.5 | – | 34.5 | 34.5 | 13 | 54 | 27 | 1.55 |

| 32 | 1 1/4 | 424 | 135 | 117.3 | 98.4 | 18 | 15.7 | 4 | 20.7 | – | 43.5 | 43.2 | 14 | 64 | 29 | 2.06 |

| 40 | 1 1/2 | 48.3 | 155 | 127 | 114.3 | 22 | 15.7 | 4 | 22.3 | – | 49.5 | 49.5 | 16 | 70 | 32 | 3.00 |

| 50 | 2 | 60.3 | 165 | 152.4 | 127 | 18 | 19.1 | 8 | 25.4 | – | 61.5 | 62 | 17 | 84 | 37 | 3.67 |

| 65 | 2 1/2 | 76.1 | 190 | 177.8 | 149.2 | 22 | 19.1 | 8 | 28.6 | – | 77.6 | 74.7 | 19 | 100 | 41 | 5.35 |

| 80 | 3 | 88.9 | 210 | 190.5 | 168.3 | 22 | 19.1 | 8 | 31.8 | – | 90.5 | 90.7 | 21 | 117 | 46 | 7.06 |

Note: The inner diameter B1 of the flange is determined by the wall thickness of the steel pipe. The user should indicate it when ordering. The flange inner diameter B1 listed in the table is equivalent to a steel pipe with a wall thickness of Sch40

| Nominal size | Steel pipe outer diameter A | Flange outer diameter D | Connection size | flange thickness C | Flange inner diameter B1 | Socket | Flange neck big end N | Flange height H | Theoretical weight Kg | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | Bolt hole center circle diameter K | Bold hole diameter L | Bolt hole Quantity n(pieces) | B2 | U | ||||||||||

| 15 | ½ | 21.3 | 120 | 120.6 | 82.6 | 22 | 22.3 | 4 | 22.3 | – | 22.5 | 22.4 | 10 | 38 | 32 | 1.8 |

| 20 | ¾ | 26.9 | 130 | 130 | 88.9 | 22 | 22.3 | 4 | 25.4 | – | 27.5 | 27.7 | 11 | 44 | 35 | 2.41 |

| 25 | 1 | 33.7 | 150 | 149.3 | 101.6 | 26 | 25.4 | 4 | 28.6 | – | 34.5 | 34.5 | 13 | 52 | 41 | 3.55 |

| 32 | 1¼ | 42.4 | 160 | 158.7 | 111.1 | 26 | 25.4 | 4 | 28.6 | – | 43.5 | 43.2 | 14 | 64 | 41 | 4.02 |

| 40 | 1½ | 48.3 | 180 | 177.8 | 123.8 | 30 | 28.4 | 4 | 31.8 | – | 49.5 | 49.5 | 16 | 70 | 44 | 5.45 |

| 50 | 2 | 60.3 | 215 | 215.9 | 165.1 | 26 | 25.4 | 8 | 38.1 | – | 61.5 | 62 | 17 | 105 | 57 | 10.2 |

| 65 | 2½ | 76.1 | 245 | 244.3 | 190.5 | 30 | 28.4 | 8 | 41.3 | – | 77.6 | 74.7 | 19 | 124 | 64 | 13.9 |

Note: The inner diameter B1 of the flange is determined by the wall thickness of the steel pipe. The user should indicate it when ordering. The flange inner diameter B1 listed in the table is equivalent to a steel pipe with a wall thickness of Sch40

ASME b16.5 Threaded Flange Dimensions

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 90 | 60.3 | 16 | 4 | M14 | 9.6 | 15.5 | 30 | 46 |

| 20 | 3/4 | 26.9 | 100 | 69.9 | 16 | 4 | M14 | 11.2 | 21 | 38 | 51 |

| 25 | 1 | 33.7 | 110 | 79.4 | 16 | 4 | M14 | 12.7 | 27 | 49 | 54 |

| 32 | 1 1/4 | 42.4 | 115 | 88.9 | 16 | 4 | M14 | 14.3 | 35 | 59 | 56 |

| 40 | 1 1/2 | 48.3 | 125 | 98.4 | 16 | 4 | M14 | 15.9 | 41 | 65 | 60 |

| 50 | 2 | 60.3 | 150 | 120.7 | 18 | 4 | M16 | 17.5 | 52 | 78 | 62 |

| 65 | 2 1/2 | 76.1 | 180 | 139.7 | 18 | 4 | M16 | 20.7 | 66 | 90 | 68 |

| 80 | 3 | 88.9 | 190 | 152.4 | 18 | 4 | M16 | 22.3 | 77.5 | 108 | 68 |

| 100 | 4 | 114.3 | 230 | 190.5 | 18 | 8 | M16 | 22.3 | 101.5 | 135 | 75 |

| 125 | 5 | 139.7 | 255 | 215.9 | 22 | 8 | M20 | 22.3 | 127 | 164 | 87 |

| 150 | 6 | 168.3 | 280 | 241.3 | 22 | 8 | M20 | 23.9 | 154 | 192 | 87 |

| 200 | 8 | 219.1 | 345 | 298.5 | 22 | 8 | M20 | 27 | 203 | 246 | 100 |

| 250 | 10 | 273 | 405 | 362 | 26 | 12 | M24 | 28.6 | 255 | 305 | 100 |

| 300 | 12 | 323.9 | 485 | 431.8 | 26 | 12 | M24 | 30.2 | 303.5 | 365 | 113 |

| 350 | 14 | 355.6 | 535 | 476.3 | 30 | 12 | M27 | 33.4 | – | 400 | 125 |

| 400 | 16 | 406.4 | 595 | 539.8 | 30 | 16 | M27 | 35 | – | 457 | 125 |

| 450 | 18 | 457 | 635 | 577.9 | 33 | 16 | M30 | 38.1 | – | 505 | 138 |

| 500 | 20 | 508 | 700 | 635 | 33 | 20 | M30 | 41.3 | – | 559 | 143 |

| 600 | 24 | 610 | 815 | 749.3 | 36 | 20 | M33 | 46.1 | – | 663 | 151 |

| Nominal size | Steel Pipe outer diameter | Connection size | flange thickness | flange inner diameter | flange neck big end | flange height | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C | B | N | H |

| 15 | 1/2 | 21.3 | 95 | 66.7 | 16 | 4 | M14 | 12.7 | 15.5 | 38 | 51 |

| 20 | 3/4 | 26.9 | 115 | 82.6 | 18 | 4 | M16 | 14.3 | 21 | 48 | 56 |

| 25 | 1 | 33.7 | 125 | 88.9 | 18 | 4 | M16 | 15.9 | 27 | 54 | 60 |

| 32 | 1 1/4 | 42.4 | 135 | 98.4 | 18 | 4 | M16 | 17.5 | 35 | 64 | 64 |

| 40 | 1 1/2 | 48.3 | 155 | 114.3 | 22 | 4 | M20 | 19.1 | 41 | 70 | 67 |

| 50 | 2 | 60.3 | 165 | 127 | 18 | 8 | M16 | 20.7 | 52 | 84 | 68 |

| 65 | 2 1/2 | 76.1 | 190 | 149.2 | 22 | 8 | M20 | 23.9 | 66 | 100 | 75 |

| 80 | 3 | 88.9 | 210 | 168.3 | 22 | 8 | M20 | 27 | 77.5 | 117 | 78 |

| 100 | 4 | 114.3 | 255 | 200 | 22 | 8 | M20 | 30.2 | 101.5 | 146 | 84 |

| 125 | 5 | 139.7 | 280 | 235 | 22 | 8 | M20 | 33.4 | 127 | 178 | 97 |

| 150 | 6 | 168.3 | 320 | 269.9 | 22 | 12 | M20 | 35 | 154 | 206 | 97 |

| 200 | 8 | 219.1 | 380 | 330.2 | 26 | 12 | M24 | 39.7 | 203 | 260 | 110 |

| 250 | 10 | 273 | 445 | 387.4 | 30 | 16 | M27 | 46.1 | 255 | 321 | 116 |

| 300 | 12 | 323.9 | 520 | 450.8 | 33 | 16 | M30 | 49.3 | 303.5 | 375 | 129 |

| 350 | 14 | 355.6 | 585 | 514.4 | 33 | 20 | M30 | 52.4 | – | 425 | 141 |

| 400 | 16 | 406.4 | 650 | 571.5 | 36 | 20 | M33 | 55.6 | – | 483 | 144 |

| 450 | 18 | 457 | 710 | 628.6 | 36 | 24 | M33 | 58.8 | – | 533 | 157 |

| 500 | 20 | 508 | 775 | 685.8 | 36 | 24 | M33 | 62 | – | 587 | 160 |

| 600 | 24 | 610 | 915 | 812.8 | 42 | 24 | M39X3 | 68.3 | – | 702 | 167 |

ASME b16.5 Lap Joint Flange Dimensions

| Nominal size | Steel Pipe outer diameter | Flange outer diameter | Connection size | flange thickness | Flange inner diameter | Flange neck big end | Flange height | Rounded comers | Butt welding ring | Theotical weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | D | Bolt hole center circle diameter K | Bolt hole diameter L | Bolt hole quantity n(pieces) | C | B | N | H | R1 | high H | outer diameter d | Kg | ||

| 15 | 1/2 | 21.3 | 90 | 88.9 | 60.3 | 16 | 15.7 | 4 | 11.2 | 22.9 | 30 | 16 | 3 | 51 | 34.9 | 0.38 |

| 20 | 3/4 | 26.9 | 100 | 98.6 | 69.9 | 16 | 15.7 | 4 | 12.7 | 28.2 | 38 | 16 | 3 | 51 | 42.9 | 0.55 |

| 25 | 1 | 33.7 | 110 | 108 | 79.4 | 16 | 15.7 | 4 | 14.3 | 34.9 | 49 | 17 | 3 | 51 | 50.8 | 0.76 |

| 32 | 1 1/4 | 42.4 | 115 | 117.3 | 88.9 | 16 | 15.7 | 4 | 15.9 | 43.7 | 59 | 21 | 5 | 51 | 63.5 | 1.01 |

| 40 | 1 1/2 | 48.3 | 125 | 127 | 98.4 | 16 | 15.7 | 4 | 17.5 | 50.0 | 65 | 22 | 6 | 51 | 73.0 | 1.3 |

| 50 | 2 | 60.3 | 150 | 152.4 | 120.7 | 18 | 19.1 | 4 | 19.1 | 62.5 | 78 | 25 | 8 | 64 | 92.1 | 2.03 |

| 65 | 2 1/2 | 76.1 | 180 | 177.8 | 139.7 | 18 | 19.1 | 4 | 22.3 | 78.5/75.4 | 90 | 29 | 8 | 64 | 104.8 | 3.25 |

| 80 | 3 | 88.9 | 190 | 190.5 | 152.4 | 18 | 19.1 | 4 | 23.9 | 91.4 | 108 | 30 | 10 | 64 | 127.0 | 3.81 |

| 100 | 4 | 114.3 | 230 | 228.6 | 190.5 | 18 | 19.1 | 8 | 23.9 | 116.8 | 135 | 33 | 11 | 76 | 157.2 | 5.25 |

| 125 | 5 | 139.7 | 255 | 254 | 215.9 | 22 | 22.4 | 8 | 23.9 | 144.4 | 164 | 36 | 11 | 76 | 185.7 | 6.02 |

| 150 | 6 | 168.3 | 280 | 278.4 | 241.3 | 22 | 22.4 | 8 | 25.4 | 171.4 | 192 | 40 | 13 | 89 | 215.9 | 7.4 |

| 200 | 8 | 219.1 | 345 | 342.9 | 298.58 | 22 | 22.4 | 8 | 28.6 | 222.2 | 246 | 44 | 13 | 102 | 269.9 | 12.1 |

| 250 | 10 | 273 | 405 | 406.4 | 362.0 | 26 | 25.4 | 12 | 30.2 | 277.4 | 305 | 49 | 13 | 127 | 323.8 | 16.4 |

| 300 | 12 | 323.9 | 485 | 482.6 | 431.8 | 26 | 25.4 | 12 | 31.8 | 328.2 | 365 | 56 | 13 | 152 | 381.0 | 26.1 |

| 350 | 14 | 355.6 | 535 | 533.4 | 476.2 | 30 | 28.4 | 12 | 35.0 | 360.2 | 400 | 79 | 13 | 152 | 412.8 | 34.5 |

| 400 | 16 | 406.4 | 595 | 596.9 | 539.8 | 30 | 28.4 | 16 | 36.6 | 411.2 | 457 | 87 | 13 | 152 | 469.9 | 44.6 |

| 450 | 18 | 457 | 635 | 635 | 577.9 | 33 | 31.75 | 16 | 39.7 | 462.3 | 505 | 97 | 13 | 152 | 533.4 | 48.7 |

| 500 | 20 | 508 | 700 | 698.5 | 635.0 | 33 | 31.75 | 20 | 42.9 | 514.4 | 559 | 103 | 13 | 152 | 584.2 | 61.6 |

| 600 | 24 | 610 | 815 | 812.8 | 749.3 | 36 | 35.1 | 20 | 47.7 | 616.0 | 663 | 111 | 13 | 152 | 692.2 | 86.6 |

| Nominal size | Steel Pipe outer diameter | Flange outer diameter | Connection size | flange thickness | Flange inner diameter | Flange neck big end | Flange height | Rounded corners | Butt welding ring | Theotical weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | D | Bolt hole center circle diameter K | Bolt hole diameter L | Bolt hole quantity n(pieces) | C | B | N | H | R1 | high H | outer diameter d | Kg | ||

| 15 | 1/2 | 21.3 | 95 | 88.9 | 66.7 | 16 | 15.7 | 4 | 14.3 | 22.9 | 38 | 22 | 3 | 51 | 34.9 | 0.62 |

| 20 | 3/4 | 26.9 | 115 | 98.6 | 82.6 | 18 | 15.7 | 4 | 15.9 | 28.2 | 48 | 25 | 3 | 51 | 42.9 | 1.1 |

| 25 | 1 | 33.7 | 125 | 108 | 88.9 | 18 | 15.7 | 4 | 17.5 | 34.9 | 54 | 27 | 3 | 51 | 50.8 | 1.33 |

| 32 | 1 1/4 | 42.4 | 135 | 117.3 | 98.4 | 18 | 15.7 | 4 | 19.1 | 43.7 | 64 | 27 | 5 | 51 | 63.5 | 1.65 |

| 40 | 1 1/2 | 48.3 | 155 | 127 | 114.3 | 22 | 15.7 | 4 | 20.7 | 50.0 | 70 | 30 | 6 | 51 | 73.0 | 2.44 |

| 50 | 2 | 60.3 | 165 | 152.4 | 127.0 | 18 | 19.1 | 8 | 22.3 | 62.5 | 84 | 33 | 8 | 64 | 92.1 | 2.83 |

| 65 | 2 1/2 | 76.1 | 190 | 177.8 | 149.2 | 22 | 19.1 | 8 | 25.4 | 78.5/75.4 | 100 | 38 | 8 | 64 | 104.8 | 4.25 |

| 80 | 3 | 88.9 | 210 | 190.5 | 168.3 | 22 | 19.1 | 8 | 28.6 | 91.4 | 117 | 43 | 10 | 64 | 127.0 | 5.78 |

| 100 | 4 | 114.3 | 255 | 228.6 | 200.0 | 22 | 19.1 | 8 | 31.8 | 116.8 | 146 | 48 | 11 | 76 | 157.2 | 9.55 |

| 125 | 5 | 139.7 | 280 | 254 | 235.0 | 22 | 22.4 | 8 | 35.0 | 144.4 | 178 | 51 | 11 | 76 | 185.7 | 12.2 |

| 150 | 6 | 168.3 | 320 | 279.4 | 269.9 | 22 | 22.4 | 12 | 36.6 | 171.4 | 206 | 52 | 13 | 89 | 215.9 | 15.5 |

| 200 | 8 | 219.1 | 380 | 342.9 | 330.2 | 26 | 22.4 | 12 | 41.3 | 222.2 | 260 | 62 | 13 | 102 | 269.9 | 24.1 |

| 250 | 10 | 273 | 445 | 406.4 | 387.4 | 30 | 25.4 | 16 | 47.7 | 277.1 | 321 | 95 | 13 | 254 | 323.8 | 34.4 |

| 300 | 12 | 323.9 | 520 | 482.6 | 450.8 | 33 | 25.4 | 16 | 50.8 | 328.2 | 375 | 102 | 13 | 254 | 381.0 | 50.4 |

| 350 | 14 | 355.6 | 585 | 533.4 | 514.4 | 33 | 28.4 | 20 | 54.0 | 360.2 | 425 | 111 | 13 | 305 | 412.8 | 70.9 |

| 400 | 16 | 406.4 | 650 | 596.9 | 571.5 | 36 | 28.4 | 20 | 57.2 | 411.2 | 483 | 121 | 13 | 305 | 469.9 | 89.5 |

| 450 | 18 | 457 | 710 | 635 | 628.6 | 36 | 31.75 | 24 | 60.4 | 462.3 | 533 | 130 | 13 | 305 | 533.4 | 111 |

| 500 | 20 | 508 | 775 | 698.5 | 685.8 | 36 | 31.75 | 24 | 63.5 | 514.4 | 587 | 140 | 13 | 305 | 584.2 | 137 |

| 600 | 24 | 610 | 915 | 812.8 | 812.8 | 42 | 35.1 | 24 | 69.9 | 616.0 | 702 | 152 | 13 | 305 | 692.2 | 204 |

| Nominal size | Steel Pipe outer diameter | Flange outer diameter | Connection size | flange thickness | Flange inner diameter | Flange neck big end | Flange height | Rounded corners | Butt welding ring | Theotical weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | D | Bolt hole center circle diameter K | Bolt hole diameter L | Bolt hole quantity n(pieces) | C | B | N | H | R1 | high H | outer diameter d | Kg | ||

| 15 | 1/2 | 21.3 | 95 | 88.9 | 66.7 | 16 | 15.7 | 4 | 14.3 | 22.9 | 38 | 22 | 3 | 76 | 34.9 | 0.72 |

| 20 | 3/4 | 26.9 | 115 | 98.6 | 82.6 | 18 | 15.7 | 4 | 15.9 | 28.2 | 48 | 25 | 3 | 76 | 42.9 | 1.25 |

| 25 | 1 | 33.7 | 125 | 108 | 88.9 | 18 | 15.7 | 4 | 17.5 | 34.9 | 54 | 27 | 3 | 102 | 50.8 | 1.5 |

| 32 | 11/4 | 42.4 | 135 | 117.3 | 98.4 | 18 | 15.7 | 4 | 20.7 | 43.7 | 64 | 29 | 5 | 102 | 63.5 | 2 |

| 40 | 11/2 | 48.3 | 155 | 127 | 114.3 | 22 | 15.7 | 4 | 22.3 | 50.0 | 70 | 32 | 6 | 102 | 73.0 | 2.92 |

| 50 | 2 | 60.3 | 165 | 152.4 | 127.0 | 18 | 19.1 | 8 | 25.4 | 62.5 | 84 | 37 | 8 | 152 | 92.1 | 3.55 |

| 65 | 21/2 | 76.1 | 190 | 177.8 | 149.2 | 22 | 19.1 | 8 | 28.6 | 78.5/75.4 | 100 | 41 | 8 | 152 | 104.8 | 5.23 |

| 80 | 3 | 88.9 | 210 | 190.5 | 168.3 | 22 | 19.1 | 8 | 31.8 | 91.4 | 117 | 46 | 10 | 152 | 127.0 | 6.95 |

| 100 | 4 | 114.3 | 275 | 228.6 | 215.9 | 26 | 19.1 | 8 | 38.1 | 116.8 | 152 | 54 | 11 | 152 | 157.2 | 14.4 |

| 125 | 5 | 139.7 | 330 | 254 | 266.7 | 30 | 22.4 | 8 | 44.5 | 144.4 | 189 | 60 | 11 | 203 | 185.7 | 24.3 |

| 150 | 6 | 168.3 | 355 | 279.4 | 292.1 | 30 | 22.4 | 12 | 47.7 | 171.4 | 222 | 67 | 13 | 203 | 215.9 | 28.5 |

| 200 | 8 | 219.1 | 420 | 342.9 | 349.2 | 33 | 22.4 | 12 | 55.6 | 222.2 | 273 | 76 | 13 | 203 | 269.9 | 43.1 |

| 250 | 10 | 273 | 510 | 406.4 | 431.8 | 36 | 25.4 | 16 | 63.5 | 277.4 | 343 | 111 | 13 | 254 | 323.8 | 70.5 |

| 300 | 12 | 323.9 | 560 | 482.6 | 489.0 | 36 | 25.4 | 20 | 66.7 | 328.2 | 400 | 117 | 13 | 254 | 381.0 | 86.1 |

| 350 | 14 | 355.6 | 605 | 533.4 | 527.0 | 39 | 28.4 | 20 | 69.9 | 360.2 | 432 | 127 | 13 | 305 | 412.8 | 100 |

| 400 | 16 | 406.4 | 685 | 596.9 | 603.2 | 42 | 28.4 | 20 | 76.2 | 411.2 | 495 | 140 | 13 | 305 | 469.9 | 145 |

| 450 | 18 | 457 | 745 | 635 | 654.0 | 45 | 31.75 | 20 | 82.6 | 462.3 | 546 | 152 | 13 | 305 | 533.4 | 177 |

| 500 | 20 | 508 | 815 | 698.5 | 723.9 | 45 | 31.75 | 24 | 88.9 | 514.4 | 610 | 165 | 13 | 305 | 584.2 | 225 |

| 600 | 24 | 610 | 940 | 812.8 | 838.2 | 51 | 35.1 | 24 | 101.6 | 616.0 | 718 | 184 | 13 | 305 | 692.2 | 318 |

ASME b16.5 Blind Flange Dimensions

| Nominal size | Connection size | flange thickness | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C |

| 15 | 1/2 | 90 | 60.3 | 16 | 4 | M14 | 9.6 |

| 20 | 3/4 | 100 | 69.9 | 16 | 4 | M14 | 11.2 |

| 25 | 1 | 110 | 79.4 | 16 | 4 | M14 | 12.7 |

| 32 | 1 1/4 | 115 | 88.9 | 16 | 4 | M14 | 14.3 |

| 40 | 1 1/2 | 125 | 98.4 | 16 | 4 | M14 | 15.9 |

| 50 | 2 | 150 | 120.7 | 18 | 4 | M16 | 17.5 |

| 65 | 2 1/2 | 180 | 139.7 | 18 | 4 | M16 | 20.7 |

| 80 | 3 | 190 | 152.4 | 18 | 4 | M16 | 22.3 |

| 100 | 4 | 230 | 190.5 | 18 | 8 | M16 | 22.3 |

| 125 | 5 | 255 | 215.9 | 22 | 8 | M20 | 22.3 |

| 150 | 6 | 280 | 241.3 | 22 | 8 | M20 | 23.9 |

| 200 | 8 | 345 | 298.58 | 22 | 8 | M20 | 27.0 |

| 250 | 10 | 405 | 362.0 | 26 | 12 | M24 | 28.6 |

| 300 | 12 | 485 | 431.8 | 26 | 12 | M24 | 30.2 |

| 350 | 14 | 535 | 476.3 | 30 | 12 | M27 | 33.4 |

| 400 | 16 | 595 | 539.8 | 30 | 16 | M27 | 35.0 |

| 450 | 18 | 635 | 577.9 | 33 | 16 | M30 | 38.1 |

| 500 | 20 | 700 | 635.0 | 33 | 20 | M30 | 41.3 |

| 600 | 24 | 815 | 749.3 | 36 | 20 | M33 | 46.1 |

| Nominal size | Connection size | flange thickness | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C |

| 15 | 1/2 | 95 | 66.7 | 16 | 4 | M14 | 12.7 |

| 20 | 3/4 | 115 | 82.6 | 18 | 4 | M16 | 14.3 |

| 25 | 1 | 125 | 88.9 | 18 | 4 | M16 | 15.9 |

| 32 | 1 1/4 | 135 | 98.4 | 18 | 4 | M16 | 17.5 |

| 40 | 1 1/2 | 155 | 114.3 | 22 | 4 | M20 | 19.1 |

| 50 | 2 | 165 | 127.0 | 18 | 8 | M16 | 20.7 |

| 65 | 2 1/2 | 190 | 149.2 | 22 | 8 | M20 | 23.9 |

| 80 | 3 | 210 | 168.3 | 22 | 8 | M20 | 27.0 |

| 100 | 4 | 255 | 200.0 | 22 | 8 | M20 | 30.2 |

| 125 | 5 | 280 | 235.0 | 22 | 8 | M20 | 33.4 |

| 150 | 6 | 320 | 269.9 | 22 | 12 | M20 | 35.0 |

| 200 | 8 | 380 | 330.2 | 26 | 12 | M24 | 39.7 |

| 250 | 10 | 445 | 387.4 | 30 | 16 | M27 | 46.1 |

| 300 | 12 | 520 | 450.8 | 33 | 16 | M30 | 49.3 |

| 350 | 14 | 585 | 514.4 | 33 | 20 | M30 | 52.4 |

| 400 | 16 | 650 | 571.5 | 36 | 20 | M33 | 55.6 |

| 450 | 18 | 710 | 628.6 | 36 | 24 | M33 | 58.8 |

| 500 | 20 | 775 | 685.8 | 36 | 24 | M33 | 62.0 |

| 600 | 24 | 915 | 812.8 | 42 | 24 | M39X3 | 68.3 |

| Nominal size | Connection size | flange thickness | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C |

| 15 | 1/2 | 95 | 66.7 | 16 | 4 | M14 | 14.3 |

| 20 | 3/4 | 115 | 82.6 | 18 | 4 | M16 | 15.9 |

| 25 | 1 | 125 | 88.9 | 18 | 4 | M16 | 17.5 |

| 32 | 1 1/4 | 135 | 98.4 | 18 | 4 | M16 | 20.7 |

| 40 | 1 1/2 | 155 | 114.3 | 22 | 4 | M20 | 22.3 |

| 50 | 2 | 165 | 127.0 | 18 | 8 | M16 | 25.4 |

| 65 | 2 1/2 | 190 | 149.2 | 22 | 8 | M20 | 28.6 |

| 80 | 3 | 210 | 168.3 | 22 | 8 | M20 | 31.8 |

| 100 | 4 | 275 | 215.9 | 26 | 8 | M24 | 38.1 |

| 125 | 5 | 330 | 266.7 | 30 | 8 | M27 | 44.5 |

| 150 | 6 | 355 | 292.1 | 30 | 12 | M27 | 47.7 |

| 200 | 8 | 420 | 349.2 | 33 | 12 | M30 | 55.6 |

| 250 | 10 | 510 | 431.8 | 36 | 16 | M33 | 63.5 |

| 300 | 12 | 560 | 489.0 | 36 | 20 | M33 | 66.7 |

| 350 | 14 | 605 | 527.0 | 39 | 20 | M36X3 | 69.9 |

| 400 | 16 | 685 | 603.2 | 42 | 20 | M39X3 | 76.2 |

| 450 | 18 | 745 | 654.0 | 45 | 20 | M42X3 | 82.6 |

| 500 | 20 | 815 | 723.9 | 45 | 24 | M42X3 | 88.9 |

| 600 | 24 | 940 | 838.2 | 51 | 24 | M48X3 | 101.6 |

| Nominal size | Connection size | flange thickness | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C |

| 15 | 1/2 | 120 | 82.6 | 22 | 4 | M20 | 22.3 |

| 20 | 3/4 | 130 | 88.9 | 22 | 4 | M20 | 25.4 |

| 25 | 1 | 150 | 101.6 | 26 | 4 | M24 | 28.6 |

| 32 | 1 1/4 | 160 | 111.1 | 26 | 4 | M24 | 28.6 |

| 40 | 1 1/2 | 180 | 123.8 | 30 | 4 | M27 | 31.8 |

| 50 | 2 | 215 | 165.1 | 26 | 8 | M24 | 38.1 |

| 65 | 2 1/2 | 245 | 190.5 | 30 | 8 | M27 | 41.3 |

| 80 | 3 | 265 | 203.2 | 33 | 8 | M30 | 47.7 |

| 100 | 4 | 310 | 241.3 | 36 | 8 | M33 | 54.0 |

| 125 | 5 | 375 | 292.1 | 42 | 8 | M39X3 | 73.1 |

| 150 | 6 | 395 | 317.5 | 39 | 12 | M36X3 | 82.6 |

| 200 | 8 | 485 | 393.7 | 45 | 12 | M42X3 | 92.1 |

| 250 | 10 | 585 | 482.6 | 51 | 12 | M48X3 | 108.0 |

| 300 | 12 | 675 | 571.5 | 55 | 16 | M52X3 | 123.9 |

| 350 | 14 | 750 | 635.0 | 60 | 16 | M56X3 | 133.4 |

| 400 | 16 | 825 | 704.8 | 68 | 16 | M64X3 | 146.1 |

| 450 | 18 | 915 | 774.7 | 74 | 16 | M70X3 | 162.0 |

| 500 | 20 | 985 | 831.8 | 80 | 16 | M76X3 | 177.8 |

| 600 | 24 | 1170 | 990.6 | 94 | 16 | M90X3 | 203.2 |

| Nominal size | Connection size | flange thickness | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C |

| 15 | 1/2 | 120 | 82.6 | 22 | 4 | M20 | 22.3 |

| 20 | 3/4 | 130 | 88.9 | 22 | 4 | M20 | 25.4 |

| 25 | 1 | 150 | 101.6 | 26 | 4 | M24 | 28.6 |

| 32 | 1 1/4 | 160 | 111.1 | 26 | 4 | M24 | 28.6 |

| 40 | 1 1/2 | 180 | 123.8 | 30 | 4 | M27 | 31.8 |

| 50 | 2 | 215 | 165.1 | 26 | 8 | M24 | 38.1 |

| 65 | 2 1/2 | 245 | 190.5 | 30 | 8 | M27 | 41.3 |

| 80 | 3 | 240 | 190.5 | 26 | 8 | M24 | 38.1 |

| 100 | 4 | 290 | 235.0 | 33 | 8 | M30 | 44.5 |

| 125 | 5 | 350 | 279.4 | 36 | 8 | M33 | 50.8 |

| 150 | 6 | 380 | 317.5 | 33 | 12 | M30 | 55.6 |

| 200 | 8 | 470 | 393.7 | 39 | 12 | M36X3 | 63.5 |

| 250 | 10 | 545 | 469.9 | 39 | 16 | M36X3 | 69.9 |

| 300 | 12 | 610 | 533.4 | 39 | 20 | M36X3 | 79.4 |

| 350 | 14 | 640 | 558.8 | 42 | 20 | M39X3 | 85.8 |

| 400 | 16 | 705 | 616.0 | 45 | 20 | M42X3 | 88.9 |

| 450 | 18 | 785 | 685.8 | 51 | 20 | M48X3 | 101.6 |

| 500 | 20 | 855 | 749.3 | 55 | 20 | M52X3 | 108.0 |

| 600 | 24 | 1040 | 901.7 | 68 | 20 | M64X3 | 139.7 |

| Nominal size | Connection size | flange thickness | |||||

|---|---|---|---|---|---|---|---|

| DN | NPS | Flange outer diameter D | Central circle diameter K | Bolt hole diameter L | Number of bolt holes n | Bolt Th | C |

| 15 | 1/2 | 135 | 88.9 | 22 | 4 | M20 | 30.2 |

| 20 | 3/4 | 140 | 95.2 | 22 | 4 | M20 | 31.8 |

| 25 | 1 | 160 | 108.0 | 26 | 4 | M24 | 35.0 |

| 32 | 1 1/4 | 185 | 130.2 | 30 | 4 | M27 | 38.1 |

| 40 | 1 1/2 | 205 | 146.0 | 33 | 4 | M30 | 44.5 |

| 50 | 2 | 235 | 171.4 | 30 | 8 | M27 | 50.9 |

| 65 | 2 1/2 | 265 | 196.8 | 33 | 8 | M30 | 57.2 |

| 80 | 3 | 305 | 228.6 | 36 | 8 | M33 | 66.7 |

| 100 | 4 | 355 | 273.0 | 42 | 8 | M39X3 | 76.2 |

| 125 | 5 | 420 | 323.8 | 48 | 8 | M45X3 | 92.1 |

| 150 | 6 | 485 | 368.3 | 55 | 8 | M52X3 | 108.0 |

| 200 | 8 | 550 | 438.2 | 55 | 12 | M52X3 | 127.0 |

| 250 | 10 | 675 | 539.8 | 68 | 12 | M64X3 | 165.1 |

| 300 | 12 | 760 | 619.1 | 74 | 12 | M70X3 | 184.2 |

What is ASME B16.5 Flange?

ASME B16.5 is a critical standard that specifies requirements for pipe flanges and flanged fittings.

It covers sizes from NPS 1/2 through NPS 24 for pressure classes 150 to 1500, and up to NPS 12 for class 2500. The standard details pressure-temperature ratings, material specifications, dimensions, tolerances, and marking requirements.

It applies to components made from cast or forged materials and includes specifications for flange types like slip-on, threaded, and weld neck flanges.

This standardization ensures consistency across industries, facilitates proper component selection, and maintains safety in piping systems.

Pressure Ratings

ASME B16.5 flanges are classified into pressure classes (150#, 300#, 600#, 900#, 1500#, 2500#) with corresponding temperature ratings. This ASME B16.5 standard defines maximum allowable working pressures at various temperatures for different flange materials.

Material Class

ASME B16.5 groups flange materials into categories (such as Group 1.1, 1.2, etc.) based on their chemical composition and mechanical properties. This standardization ensures proper material selection for specific operating conditions.

Dimensional Standards

The ASME B16.5 specification provides precise dimensional requirements for flange face-to-face length, thickness, bolt hole size and positioning, raised face height, and overall diameter, ensuring universal interchangeability.

Flange Face Types

ASME B16.5 flanges feature various face types including raised face (RF), flat face (FF), ring-type joint (RTJ), and large/small tongue-and-groove, accommodating different sealing requirements and applications.

Size Range Coverage

ASME B16.5 standard covers flange sizes from NPS 1/2 through NPS 24 inches, making it the most widely used specification for small to medium-sized pipe flanges in industrial applications.

Surface Finishing

ASME B16.5 specifies surface finish requirements for different flange faces, particularly for raised face flanges, ensuring proper gasket seating and leak-tight connections under various service conditions.

ASME B16.5 FLANGE DIMENSIONS

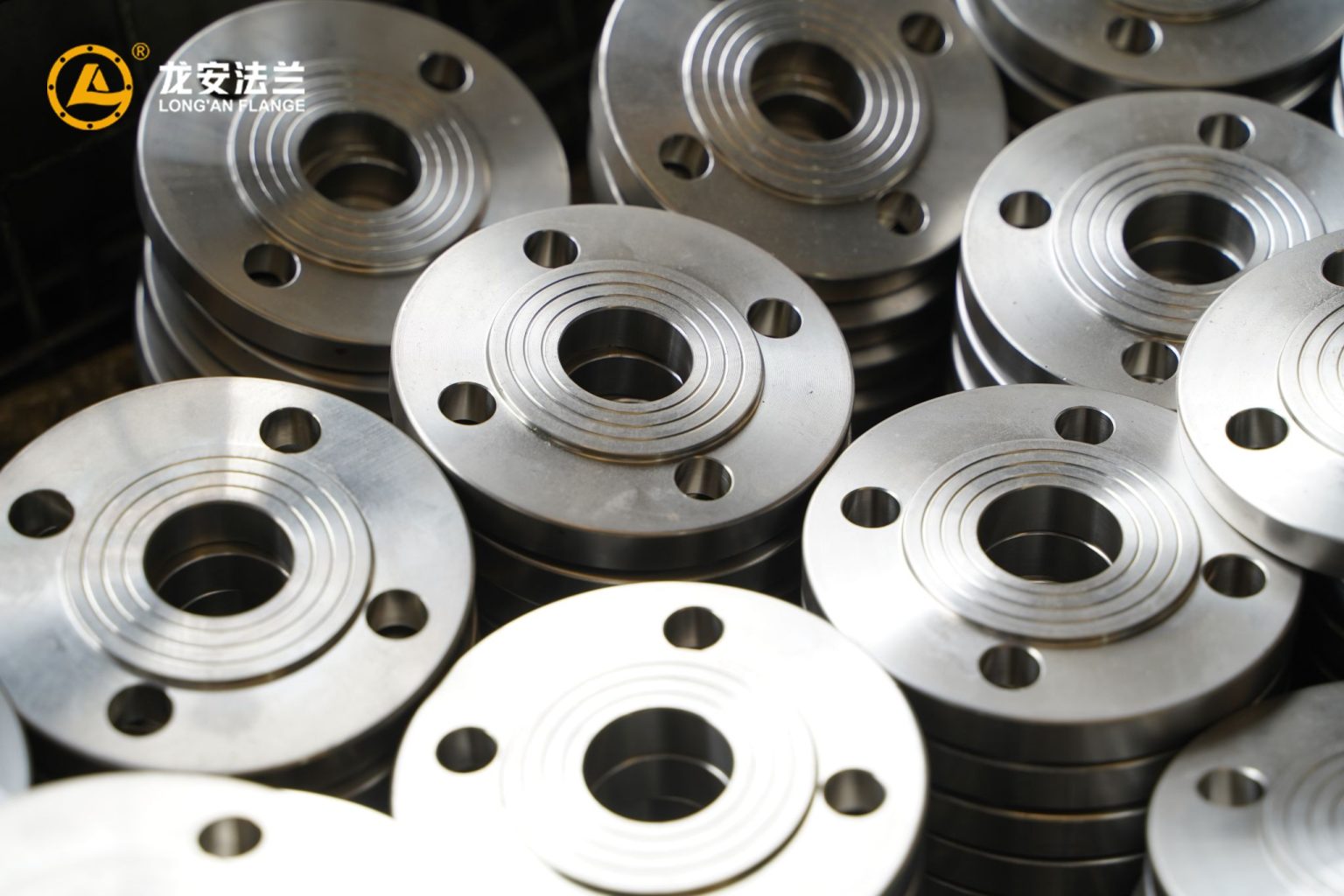

Precision-Certified Flange Solutions

Longan Flange offers expert manufacturing with advanced technology and rigorous quality control.

- ASME-Certified Expertise

- 100+ CNC Machining Units

- 15-Point Quality Assurance

- Custom-Standard Hybrid Solutions

- Dual ISO 9001/PED Certification

Exhibition

Unlock Bulk Order Savings: Claim Exclusive Pricing for Custom Flanges

Please complete our request form or contact us directly via email at [email protected], phone at +86-15258415825, or WhatsApp for a personalized quote from our product specialists.

The most common types of ASME flanges include slip-on flanges, weld neck flanges, socket weld flanges, blind flanges, lap joint flanges, and threaded flanges. Each type has specific applications and installation methods.

ASME B16.5 is a standard that specifies requirements for pipe flanges and flanged fittings, covering sizes from NPS ½” to 24” and pressure classes from 150 to 2500. It details dimensions, materials, pressure-temperature ratings, and testing requirements.

When selecting an ASME flange, consider factors such as material compatibility, pressure-temperature ratings, flange type (e.g., slip-on or weld neck), and the specific requirements of your piping system.

ASME flanges are typically made from materials such as carbon steel, stainless steel, and alloy steel. The choice of material depends on the application and environmental conditions

The pressure class rating indicates the maximum allowable pressure for a flange at a given temperature. Common classes include 150, 300, 600, 900, 1500, and 2500

While ASME flanges are designed to meet specific standards, they may not be directly interchangeable with other types like ASTM flanges without verifying that they meet necessary dimensional and pressure ratings

Flange facing types (such as raised face or flat face) affect how well the flange seals with gaskets and impacts its performance in high-pressure applications

ASME flanges undergo various tests to ensure they meet safety and performance standards, including pressure testing, material verification, and dimensional checks

ASME flanges are widely used in industries such as oil and gas, chemical processing, power generation, water treatment, food processing, and marine applications due to their reliability and adherence to safety standards

ANSI (American National Standards Institute) focuses on establishing engineering standards while ASME (American Society of Mechanical Engineers) focuses on mechanical device standards. Both organizations work together to ensure universal engineering standards; however, ASME standards often include more detailed specifications related to pressure ratings and design criteria