STAINLESS STEEL FLANGE

Longan, ISO certificated Stainless Steel Flange Factory, offering High Quality Stainless Steel flanges made from stainless steel, duplex stainless steel, and other specialized metals with BEST PRICE, compliant with AWWA, ANSI, ASME, DIN, JIS, GB and BS.

Home » Industrial Stainless Steel Flange Manufacturer | Longan

PRODUCT CATALOG

Get Instant Data & Drawings for Your custom flange Solution

AVAILABLE STAINLESS STEEL FLANGE GRADES & COMPOSITION

| Type | Grade of Steel | Chemical component(mass fraction)% | |||||||||||

| C | Si | Mn | Cr | Ni | Mo | Cu | Ti | Nb | N | P | S | ||

| Austenitic | S30408 | ≤0.08 | ≤1.00 | ≤2.00 | 18.00-20.00 | 8.00-10.50 | — | —— | —— | — | — | ≤0.035 | ≤0.020 |

| S30403 | ≤0.030 | ≤1.00 | ≤2.00 | 18.00-20.00 | 8.00-12.00 | — | — | — | — | — | ≤0.035 | ≤0.020 | |

| S30409 | 0.4-0.10 | ≤1.00 | ≤2.00 | 18.00-20.00 | 8.00-10.50 | — | — | — | — | — | ≤0.035 | ≤0.020 | |

| S32168 | ≤0.08 | ≤1.00 | ≤2.00 | 17.00-19.00 | 9.00-12.00 | — | — | 5xC-0.70 | — | — | ≤0.035 | ≤0.020 | |

| S34779 | 0.04-0.10 | ≤1.00 | ≤2.00 | 17.00-19.00 | 9.00-12.00 | — | — | — | 8xC-1.10 | — | ≤0.035 | ≤0.020 | |

| S31608 | ≤0.08 | ≤1.00 | ≤2.00 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | — | — | — | — | ≤0.035 | ≤0.020 | |

| S31603 | ≤0.030 | ≤1.00 | ≤2.00 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | — | — | — | — | ≤0.035 | ≤0.020 | |

| S31609 | 0.04-0.10 | ≤1.00 | ≤2.00 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | — | — | — | — | ≤0.035 | ≤0.020 | |

| S31668 | ≤0.08 | ≤1.00 | ≤2.00 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | — | 5xC-0.70 | — | — | ≤0.035 | ≤0.020 | |

| S31703 | ≤0.030 | ≤1.00 | ≤2.00 | 18.00-20.00 | 11.00-15.00 | 3.00-4.00 | — | —— | — | — | ≤0.035 | ≤0.020 | |

| S31008 | 0.04-0.08 | ≤1.00 | ≤2.00 | 24.00-26.00 | 19.00-22.00 | — | — | — | — | — | ≤0.035 | ≤0.020 | |

| S39042 | ≤0.020 | ≤1.00 | ≤2.00 | 19.00-21.00 | 24.00-26.00 | 4.00-5.00 | 1.20-2.00 | — | — | ≤0.10 | ≤0.030 | ≤0.010 | |

| Austenitic Monotonic Type | S21953 | ≤0.030 | 1.30-2.00 | 1.00-2.00 | 18.00-19.50 | 4.50-5.50 | 2.50-3.00 | — | — | —— | 0.05-0.12 | ≤0.030 | ≤0.020 |

| S22253 | ≤0.030 | ≤1.00 | ≤2.00 | 21.00-23.00 | 4.50-6.50 | 2.50-3.00 | — | — | — | 0.08-0.20 | ≤0.030 | ≤0.020 | |

| S22053 | ≤0.030 | ≤1.00 | ≤2.00 | 22.00-23.00 | 4.50-6.50 | 3.00-3.50 | — | — | — | 0.14-1.10 | ≤0.030 | ≤0.020 |

OUR AUSTENITIC STAINLESS STEEL FLANGE IN GRADING SYSTEMS

| No. | China | America | Korea | European Union BSEN | India IS | Australia AS | Taiwan,China CNS | |||

| Old Brand | New Brand (07.10) | Japan | ASTM | UNS | KS | |||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N²⁰ | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | — | — | 202 |

| 3 | 1Cr17Ni17 | 12Cr17Ni7 | SUS3014 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | — | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | — | — | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | — | — | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | 530500 | STS305 | 1.4303 | — | 305 | 305 |

STAINLESS STEEL FLANGE BY GRADES

304/304L Series Stainless Steel Flange

The 304 and 304L stainless steel flanges differ mainly in carbon content (0.08% vs 0.03%). 304 serves general industrial use in food and chemical equipment, while 304L excels in welded systems. Both contain 18% chromium and 8% nickel, with 304L preventing weld point corrosion, making it better for maintenance-heavy applications.

316L Series Stainless Steel Flange

316L steel flanges is the premium choice for harsh environments. It’s got 2% molybdenum added to the mix, making it tougher against corrosion than 304. The low carbon content (0.03%) means better welding properties. Marine equipment, chemical processing, and pharmaceutical plants use this grade extensively. When you need flanged stainless steel fittings that can handle aggressive chemicals or saltwater, 316L delivers.

2205 (F51) Duplex Metal Flange

2205 is the workhouse of the duplex range. With 22% chromium and 5% nickel, it’s twice as strong as regular stainless steel flanges. It resists corrosion better than 304 or 316L and costs less than super duplex options. Oil rigs, chemical plants, and high-pressure systems rely on 2205 flanges. It’s the sweet spot between performance and price for demanding applications.

2507 (F53) Super Duplex Steel Pipe Flange

2507 is the tank of flange materials. 25% chromium and 7% nickel make it virtually bulletproof against corrosion. It’s the strongest option in the lineup. Offshore platforms, desalination plants, and high-pressure chemical systems use 2507 flanges. When failure isn’t an option, and budget isn’t your primary concern, this is your material.

TP310S Stainless Steel Flange

TP310S handles extreme heat like a champion. With 25% chromium and 20% nickel, it’s built for high-temperature applications. You’ll find these flanges in furnaces, heat exchangers, and hot chemical processing. When your system runs hot enough to make other grades sweat, TP310S keeps its cool.

TP321 Stainless Steel Pipe Flange

TP321 is the titanium-enhanced version of 304. The titanium addition prevents corrosion issues during welding and high-temperature use. Aircraft parts, chemical processors, and pressure vessels use this grade. It’s the go-to choice when you need a ss flange that can handle both heat and frequent welding without compromising strength or corrosion resistance.

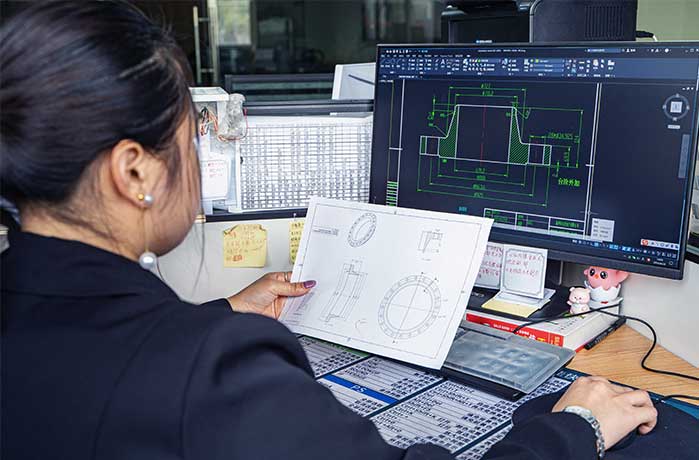

SS Flange Customized Service

According to customers’ special requirements, we provide customized stainless steel flange products and services, such as non-standard size flanges, special material flanges, etc.

SS Flange Forging Process Service

Utilizing advanced CNC processing equipment and techniques, we manufacture flanges of various materials, specifications, and standards, such as 304 stainless steel flanges, etc.

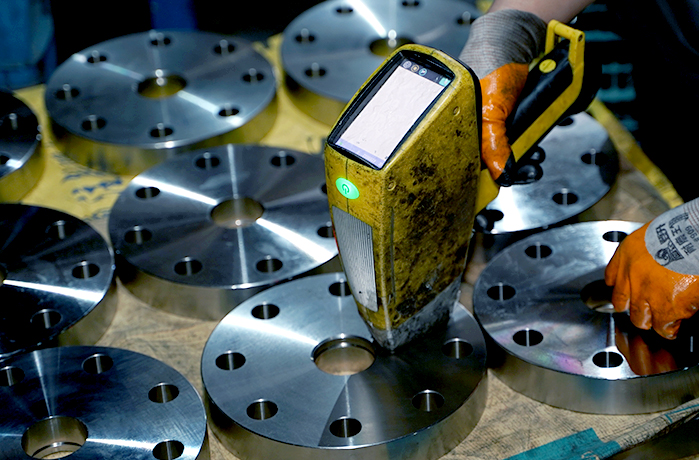

SS Flange Quality Testing

Conduct rigorous quality testing on the manufactured stainless steel flanges, including dimensional measurement, pressure testing, non-destructive testing and so on to ensure that the stainless steel flange meet relevant standards and customers’ requirements.

24/7 SS Flange Installation Guidance

We provide customers with installation guidance and technical support for stainless steel flanges, ensuring that the stainless steel flanges are correctly and safely installed into the pipeline system.

Top 5 Factors to Consider When Buying Stainless Steel Flanges in Bulk

- Consistent Quality: Grade, dimensions, pressure ratings must be uniform. Verify with EN 10204 3.1 certifications.

- Supplier Reliability: Vet capacity, supply chain, and certifications (ISO 9001). Get samples and consider site audits.

- Cost-Effectiveness: Optimize logistics, negotiate discounts, and factor in long-term costs (failures, downtime).

- Standard Compliance: Ensure adherence to ASME, DIN, ISO standards. Third-party inspection recommended.

- Robust Quality Control: Multi-stage process: pre-production samples, during-production checks, post-production testing.

Precision-Certified ss Flange Solutions

Longan Flange offers expert manufacturing with advanced technology and rigorous quality control.

- ISO-Certified Expertise

- 100+ CNC Machining Units

- 15-Point Quality Assurance

- Custom-Standard Hybrid Solutions

- Dual ISO 9001/PED Certification

EXHIBITION

Unlock Bulk Order Savings: Claim Exclusive Pricing for Custom Flanges

Please complete our request form or contact us directly via email at [email protected], phone at +86-15258415825, or WhatsApp for a personalized quote from our product specialists.

Yes, we are the manufacturer. Long’an Flange specializes in manufacturing various types of flanges and customizing non-standard products.

Our pricing is based on quality advantages at the same price point

Yes, we provide certifications. We have obtained many domestic and international certifications, including CE, Quality Management System, and Environmental Management System certifications.

We accept Letter of Credit (L/C), Telegraphic Transfer (T/T), and Document against Payment (D/P) as payment methods.

When you buy forged flange parts, you don’t have to buy a certain amount. But if you want a length that’s more than 2 meters, you’ll need to buy at least 10 pieces.

It usually takes us 2 to 4 weeks to make your order, but it depends on how complicated it is and how busy we are.

Yes, we offer OEM services for customized non-standard flanges.

We package our big, heavy flanges in wooden crates and the small, light ones in cardboard boxes. The choice depends on what kind of flange it is, its size, weight, and how far it needs to be transported.

We offer many ways to ship your items, like by truck or boat. We’ll find the best way for you based on your needs.

Verify certifications (ISO 9001, EN 10204 3.1), and ensure standards compliance (ASME, DIN). Assess production capacity and vet legitimacy (licenses, financials). Rigorous quality control is key: demand pre-production samples and inspect throughout. Consider communication and cultural fit. Understand their supply chain and negotiate contracts carefully. Don’t skip the site visit (or third-party inspection) for firsthand verification. Due diligence ensures a trustworthy supplier for your 304 stainless steel flanges.

Strategic sourcing is key: negotiate volume discounts and consider global options. Optimize flange design and standardize specifications. Improve inventory management with JIT or VMI. Streamline procurement via e-procurement and blanket orders. Optimize logistics and shipping costs. Prioritize quality and reliability to minimize defects and lifecycle costs. Monitor market trends (steel prices, currency). Don’t sacrifice quality for price. Strong supplier relationships are vital. Continuously improve your process for maximum savings.